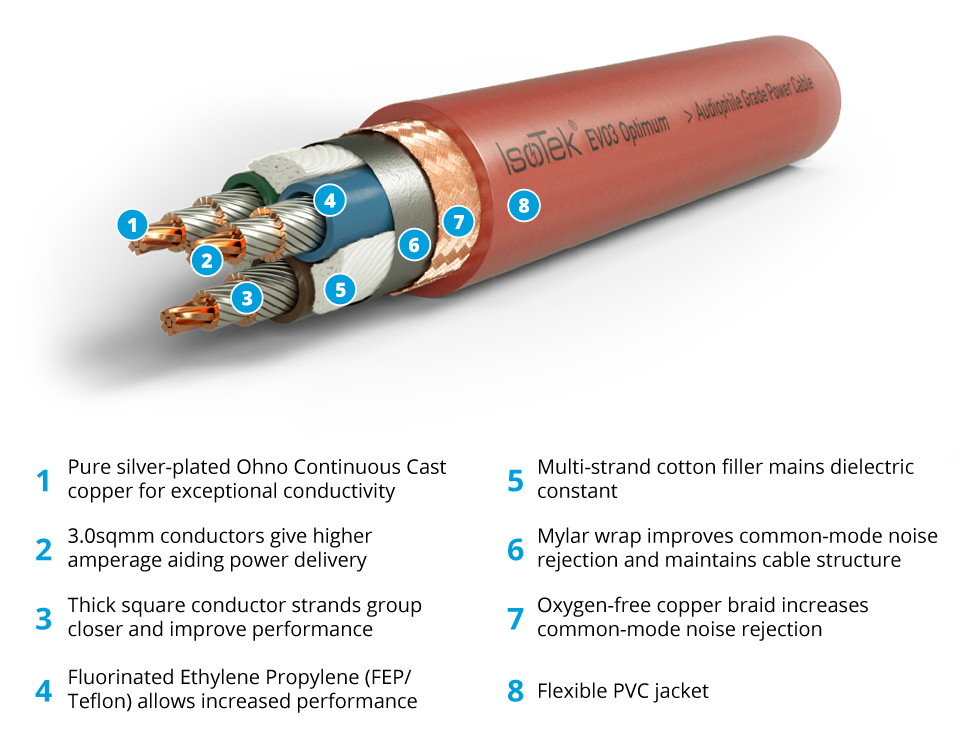

At the Optimum’s core are three silver plated Ohno Continuous Cast (OCC) copper conductors, with each conductor strand being of a square configuration for tighter bunching. The OCC offers a vastly superior level of purity with outstanding electrical conductivity, improved flexibility, resistance to fatigue and corrosion.

A high quality FEP provides a very low dielectric constant over a wide frequency range. The three conductors are given a slight rotational twist to aid RFI and EMI rejection, and are then surrounded by a cotton filler which give internal strength and reduce microphony. The whole construction is enclosed in a Mylar wrap to provide an additional dielectric buffer, before applying an active OFC shield for maximum rejection of high frequency interference. A durable PVC outer jacket gives a high degree of flexibility and mechanical strength.

CONSTRUCTION: The conductors are in a parallel configuration with a slight rotational twist. This established technique remains the first line of defence against RFI and EMI rejection.

A) Conductors: 3.0sqmm silver-plated Ohno Continuous Cast copper conductors offer a vastly superior level of purity compared with traditional OFC. Each conductor strand is of an innovative square-shaped configuration. The geometry and metallurgy used in this construction offers superb performance with extremely impressive electrical conductivity.

B) Dielectric: Teflon FEP dielectric (insulation) is chemically inert and has a very low dielectric constant over a wide frequency range. FEP possesses a very high degree of stress crack resistance and a low coefficient of friction making it an exceptional dielectric. FEP is the first choice for safety in both temperature and electrical insulation.

C) Filler: Cotton filler has been used to give the cable internal strength and reduce microphony. Cotton also possesses excellent dielectric properties, the best of any solid material.

D) Wrap: A Mylar wrap is used to secure the construction and offer a barrier shield prior to the application of a flexible PVC jacket. The addition of the Mylar and cotton form a buffer with the PVC so as to maintain exceptional dielectric properties.

E) Shield: An earthed OFC shield insures maximum RFI rejection, thus preventing common mode noise affecting the live and neutral conductors.

F) Jacket: PVC is used as an outer jacket to give a high degree of flexibility and mechanical strength.

TERMINATION: The Optimum cable is terminated using IsoTek’s bespoke audiophile-grade connectors of solid OFC with 24ct gold-plated conductors. These offer the highest quality performance and are less prone to tarnish.

As one would expect the internal wiring of any IsoTek product is of the highest standard, ultra pure Ohno Continuous Cast copper solid core conductor strands with silver-plating offer low resistance and high amperage. A Fluorinated Ethylene Propylene (FEP) helix is wound around the conductor before an extruded FEP dielectric protects the conductor and creates a Virtual Dielectric of Air (VDA). This construction gives unrivalled performance and gives the ultimate low resistance, high performance internal power delivery system.

IsoTek’s internal wiring synergizes with the range of IsoTek power cables. One critical but overlooked area is maintaining commonality of design and material properties though an audio wiring loom, be it signal carrying cables or your power cable network.

Every IsoTek product uses the finest grade electrical components, many custom made, using the highest quality metals and materials which are specifically designed for purpose. Quality doesn’t stop at parts but also extends into the PCB designs, which maintain high levels of amperage and extraordinary low levels of resistance, using up to eight times the general standard of copper prior to pure silver plating.

Internal wiring also uses high purity coppers combined with silver plating, with either Fluorinated Ethylene Propylene (FEP) dielectric or IsoTek’s Virtual Dielectric of Air (VDA), where a FEP tube is wound around the conductor before an extruded FEP dielectric protects this construction giving unrivalled performance and the ultimate low resistance, high performance internal power delivery system.

As one would expect the internal wiring of any IsoTek product is of the highest standard, ultra pure Ohno Continuous Cast copper solid core conductor strands with silver-plating offer low resistance and high amperage. A Fluorinated Ethylene Propylene (FEP) helix is wound around the conductor before an extruded FEP dielectric protects the conductor and creates a Virtual Dielectric of Air (VDA). This construction gives unrivalled performance and gives the ultimate low resistance, high performance internal power delivery system.

IsoTek’s internal wiring synergizes with the range of IsoTek power cables. One critical but overlooked area is maintaining commonality of design and material properties though an audio wiring loom, be it signal carrying cables or your power cable network.

Every IsoTek product uses the finest grade electrical components, many custom made, using the highest quality metals and materials which are specifically designed for purpose. Quality doesn’t stop at parts but also extends into the PCB designs, which maintain high levels of amperage and extraordinary low levels of resistance, using up to eight times the general standard of copper prior to pure silver plating.

Internal wiring also uses high purity coppers combined with silver plating, with either Fluorinated Ethylene Propylene (FEP) dielectric or IsoTek’s Virtual Dielectric of Air (VDA), where a FEP tube is wound around the conductor before an extruded FEP dielectric protects this construction giving unrivalled performance and the ultimate low resistance, high performance internal power delivery system.

| CONDUCTOR SIZE | 3 x 3.0sqmm (square conductor strands) |

| CONDUCTOR MATERIAL | Silver-plated Ohno Continuous Cast Copper |

| DIELECTRIC | Flourinated Ethylene Propylene (FEP) |

| DIELECTRIC CONSTANCE | 2.1 |

| FILLER | Cotton |

| PVC BARRIER | Mylar |

| SHIELD | Oxygen free copper braid (OFC) |

| OUTER JACKET | High flexibility PVC |

| CABLE POWER RATING | 30Amp |

| CABLE LENGTH | 2m, 3m, 5m standard (custom lengths available) & System Link 0,5m, 1m, 2m |

| OUTER DIAMETER | 12.5 mm |

| TERMINATION | 24ct gold plated audiophile-grade connectors |

A high quality FEP provides a very low dielectric constant over a wide frequency range. The three conductors are given a slight rotational twist to aid RFI and EMI rejection, and are then surrounded by a cotton filler which give internal strength and reduce microphony.

A high quality FEP provides a very low dielectric constant over a wide frequency range. The three conductors are given a slight rotational twist to aid RFI and EMI rejection, and are then surrounded by a cotton filler which give internal strength and reduce microphony.

IsoTek collaborates with trusted distributors worldwide to ensure top-quality support for its products and provide you with exceptional local service from certified professionals. Choose your country to find an authorized IsoTek supplier near you.

Vous devez charger le contenu de reCAPTCHA pour soumettre le formulaire. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informationsVous êtes actuellement en train de consulter le contenu d'un espace réservé de Turnstile. Pour accéder au contenu réel, cliquez sur le bouton ci-dessous. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informationsVous êtes actuellement en train de consulter le contenu d'un espace réservé de Facebook. Pour accéder au contenu réel, cliquez sur le bouton ci-dessous. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informationsVous êtes actuellement en train de consulter le contenu d'un espace réservé de Google Maps. Pour accéder au contenu réel, cliquez sur le bouton ci-dessous. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informationsVous êtes actuellement en train de consulter le contenu d'un espace réservé de Instagram. Pour accéder au contenu réel, cliquez sur le bouton ci-dessous. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informationsVous êtes actuellement en train de consulter le contenu d'un espace réservé de X. Pour accéder au contenu réel, cliquez sur le bouton ci-dessous. Veuillez noter que ce faisant, des données seront partagées avec des providers tiers.

Plus d'informations